Olimpa

Olimpa was established in 2019 at Turkey to produce hydraulic breaker, attachments and spare parts.

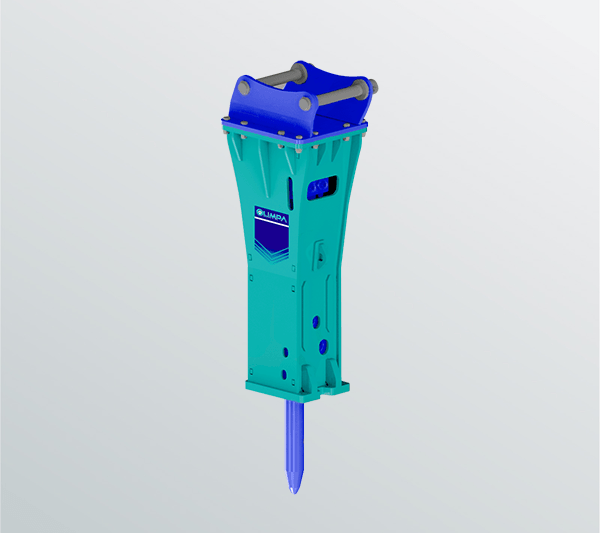

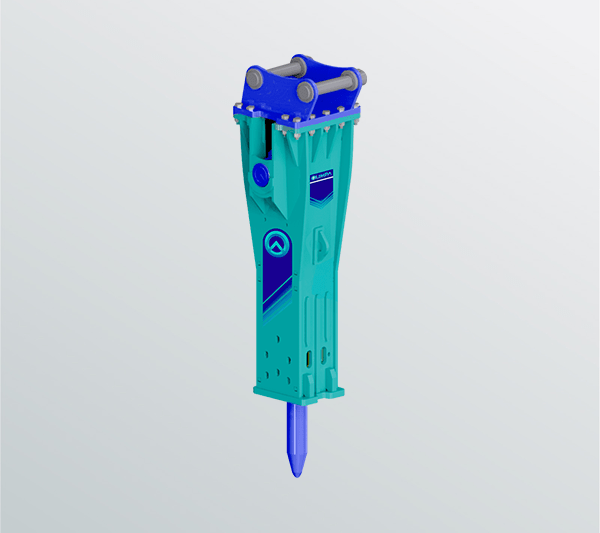

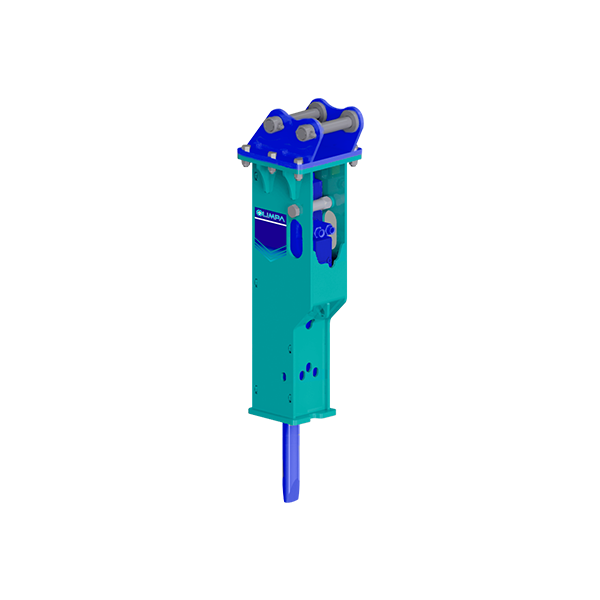

Anti Blank-Firing Smart Hydraulic Breakers

Olimpa has developed the OLP series of smart hydraulic breakers with no-load protection, for the first time in Turkey, with its expert engineer staff with many years of experience in the industry, thus increasing the durability of the breakers and bringing smart breakers to both domestic and international markets. presented.ı geliştirmiş, bu sayede kırıcıların dayanıklılığını artırmış ve akıllı kırıcıları hem yurt içi hem de yurt dışı pazarına sunmuştur.

High quality standards in crusher production

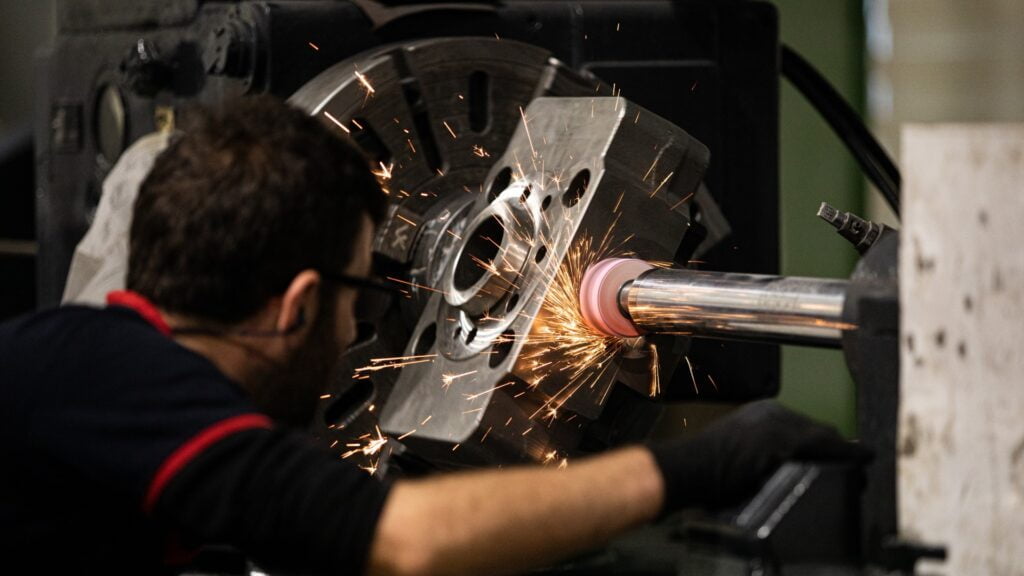

Olimpa subjects the crushers it produces to all kinds of strength tests for high quality standards.

Promotion film Play Video

01

03

idle strike protectionsystem!With The Idle strike Feature, Olimpa smart breakers Are More Robust, More Durable ! Olimpa has developed the idle strike protectionsystem in order to completely prevent the effect of idle strike in its breakers.

Olimpa has developed the idle strikeprotection system in order to completely prevent the effect of idle strikein its crushers.

Breaker parts are subjected to impact, high frequency and vibration stresses. No matter how high the strength of the steel, the principle of impact and vibration causes fatigue and damage to the steel.

Watch out for these!Things to know for crusher selection...

- Penetrating Crushing (Primary Crushing): This is the method in which the bit penetrates the rock and breaks it. This method is applied by breaking the rock out of the ground.

- Impact Crushing (Secondary Crushing): The bit applies mechanical vibration to the rock and creates stress on the rock surface, causing the rock to break. This method is applied for the crushing of large rock fragments separated from the ground. Absolutely not applicable for ground breaking. Only the blunt tip is used for this crushing method.

- Pointed Tip: Used for breaking sedimentary, soft, non-abrasive and weak metamorphic rocks. This chisel selection is made for concrete crushing, excavation and tunneling. Suitable for primary crushing.

- Chisel Chisel: It is used for breaking sedimentary, low abrasive, weak metamorphic rocks and non-abrasive but difficult to break ductile rocks. This chisel selection is made for concrete crushing, excavation and tunneling. It is the most effective chisel type for primary crushing and excavation crushing.

- Pyramid Tip: Used for breaking sedimentary, soft, non-abrasive and weak metamorphic rocks. This chisel selection is a good choice for breaking concrete. Suitable for primary crushing. It is the tip type with the highest ground penetration.

Play Video

With the feature of Anti Blank-Firing;

OLP Series is more robust, more durable!

ProductsProducts

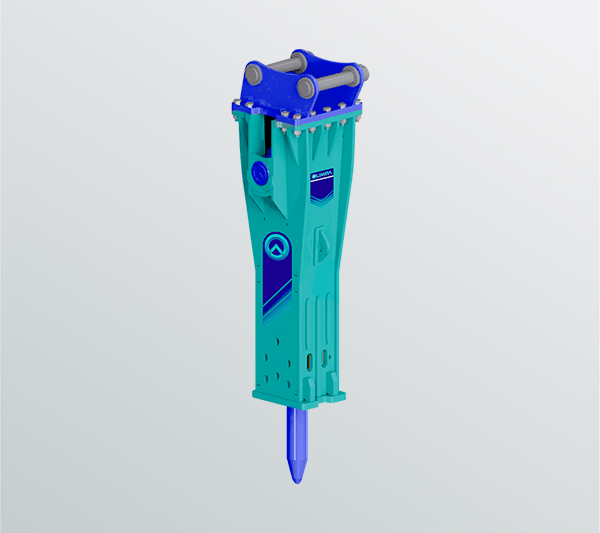

BREAKERS Hydraulic Type Breakers

- 15 models of OLP Series breakers are available in different sizes to be used in construction machines ranging from 5 to 100 tons.

- Tunnel construction,

- Underwater applications in harbors and coastal areas,

- As a primary crushing operation, it is used in direct mine dismantling or in the reduction of large rocks after blasting.

- With superior design and power, the crushing volume produced per unit time provides high performance and efficiency. Maintenance costs are also low.

View filters

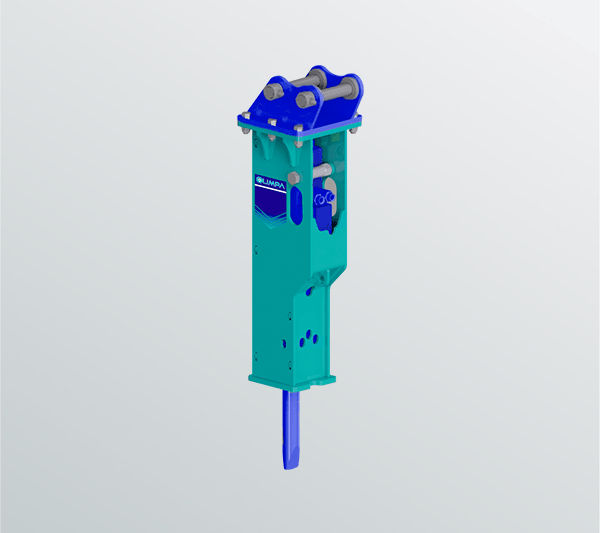

BREAKERS Gas Type Crushers

- The nitrogen gas at the top of the piston is compressed and the pressure creates impact energy.

- Developed for skid-steer-loaders and mini excavators with high return pressure.

- Works on mini excavators weighing between 1 ton and 5 tons.

- 5 tons to 10 tons curved chassis type has been developed suitable for backhoe loaders.

- It offers optimum power and performance with low investment cost.

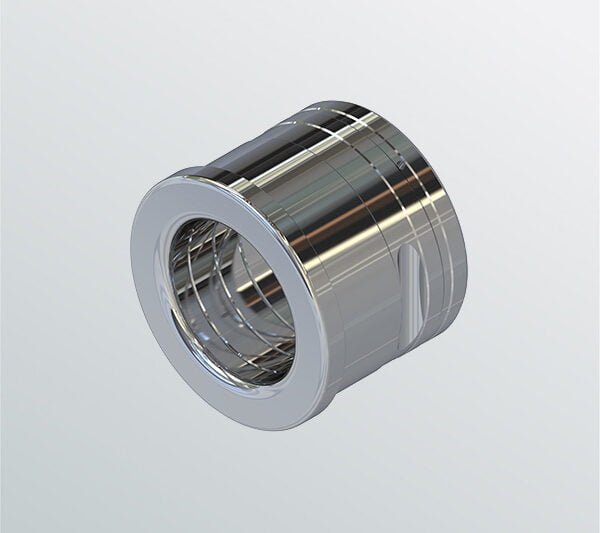

SPARE PART Spare Parts

- Chisel

- Bushings

- Retainer

- Tie Rod

- Piston

- Cylinder

- Front Head

- Accumulator

- Valve Body

- Repair Kits

- Damping Buffer

- Wear Resistant Housing

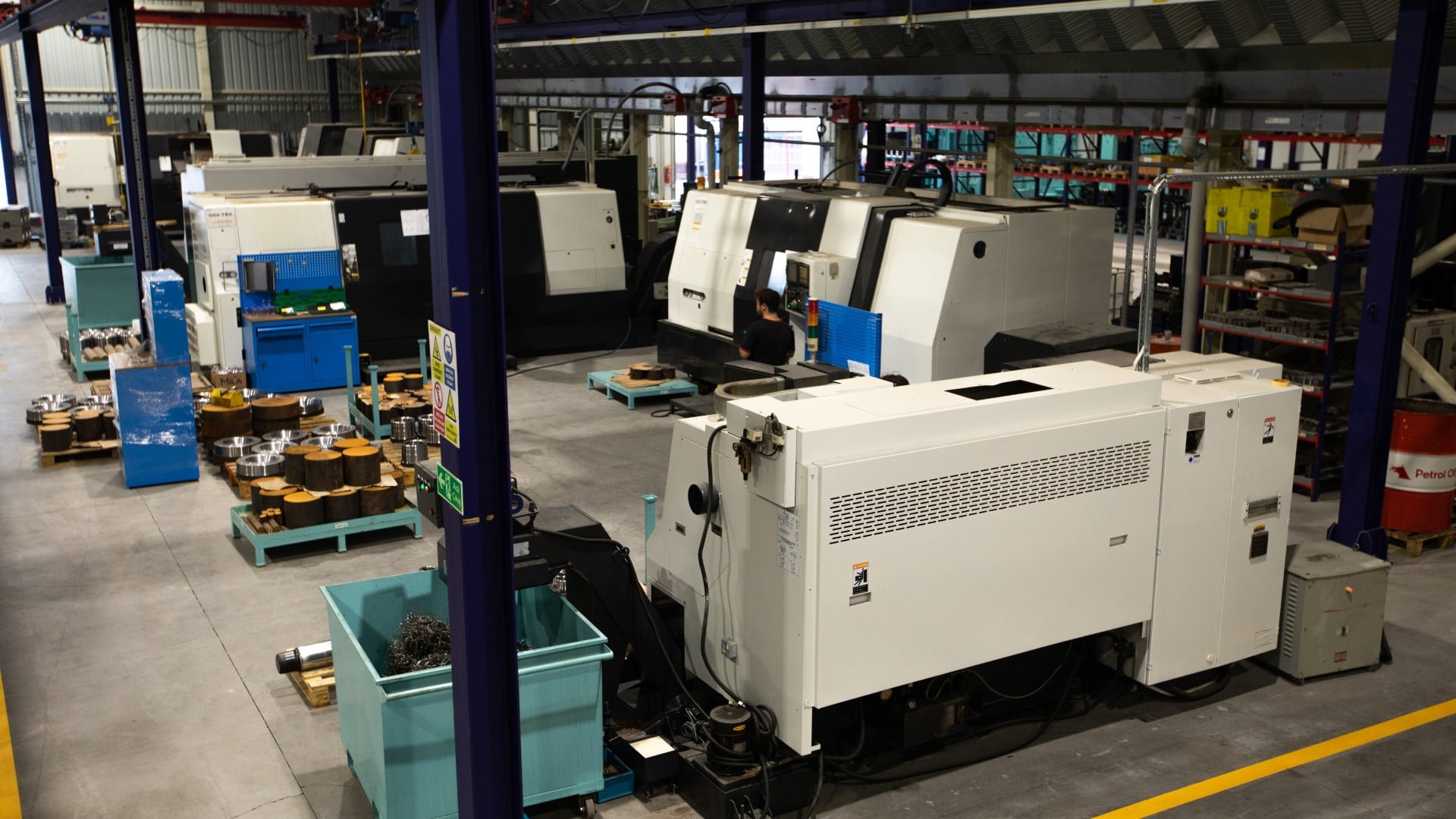

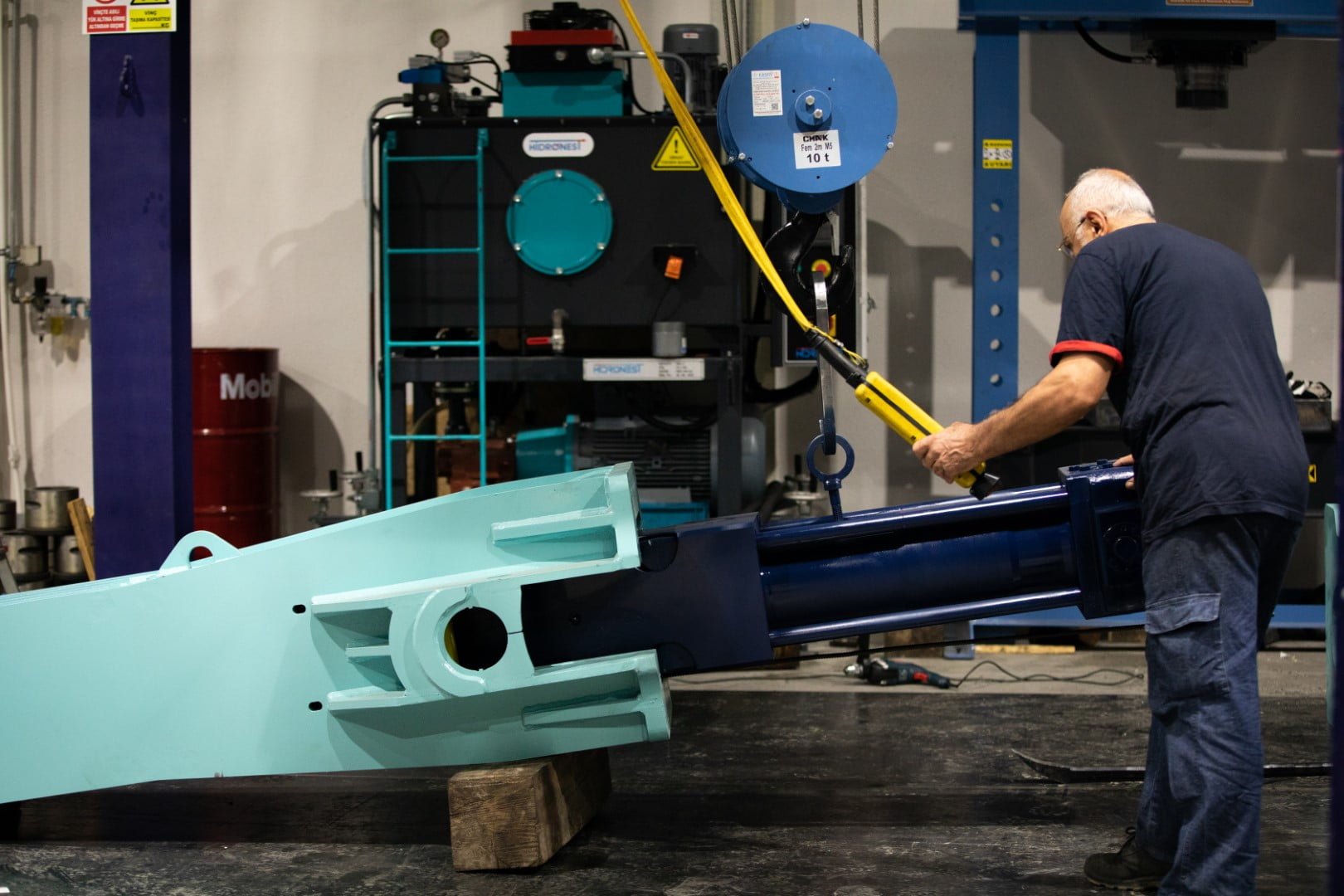

Images from the production line